Earlier this week, the US Food and Drug Administration approved the world’s first ever 3D-printed drug. Aside from being an astronomic breakthrough for the pharmaceutical industry, this news comes amid a flurry of similar stories; each demonstrating the growing potential and endless possibilities of 3D printing.

Upon its invention, 3D printing was limited in terms of its usability. Aside from architects building advanced 3D mock-ups, fashion designers producing radical new garment designs, and tech enthusiasts creating toys and other novelty bric-a-brac, the full potential of 3D printing took several months to materialise.

Now however, 3D printing has become a tech juggernaut, with hundreds of enterprises developing new, innovative ways to exploit the technology. As applications multiply and prices fall, more and more businesses are implementing 3D printing technology in a bid to rethink their operational strategy and reap market share ahead of their competitors.

Given the far-reaching implications of 3D printer tech however, the question must be asked: to what extent will 3D printing impact small businesses?

Local manufacturing

One of the primary implications of 3D printer tech for small businesses is the ability to manufacturer goods locally or even onsite. The benefits of this are far-reaching, as enterprises have in the past been solely reliant on outsourcing manufacturing to large, centralised plants; many of which are located overseas.

With the ability to manufacturer goods locally, small businesses will effectively reduce their operating costs, simplify manufacturing and lessen their environmental impact by reducing their carbon footprint, which is good news for the eco-conscious.

Cheaper costs

One of the most attractive implications posed by 3D printing technology however, is the cost. Yes, high-end 3D printers still incur high initial purchase costs, but prices are dropping by the day. Should a small business invest in a 3D printer, or seek a 3D printing manufacturer in their local area, the reduced production and shipping cost will offset the purchase price of the printer itself, potentially saving enterprises hundreds in excess operating costs.

Streamlined processes

While contemporary manufacturing has become more rapid in recent years, 3D printing technology offers a new level of efficient, cost-effective product development. Implement 3D printing technology, and small businesses will effectively eliminate the need for an assembly and manufacturing process, reducing any previous turnaround period and removing the need for stringent supply chain management.

This Harvard Business Review article examines the implications of how 3D printers can streamline the supply, manufacturing and retail process, highlighting the ways in which businesses can scale and manage operations to meet both economic and efficiency targets.

Greater customisation

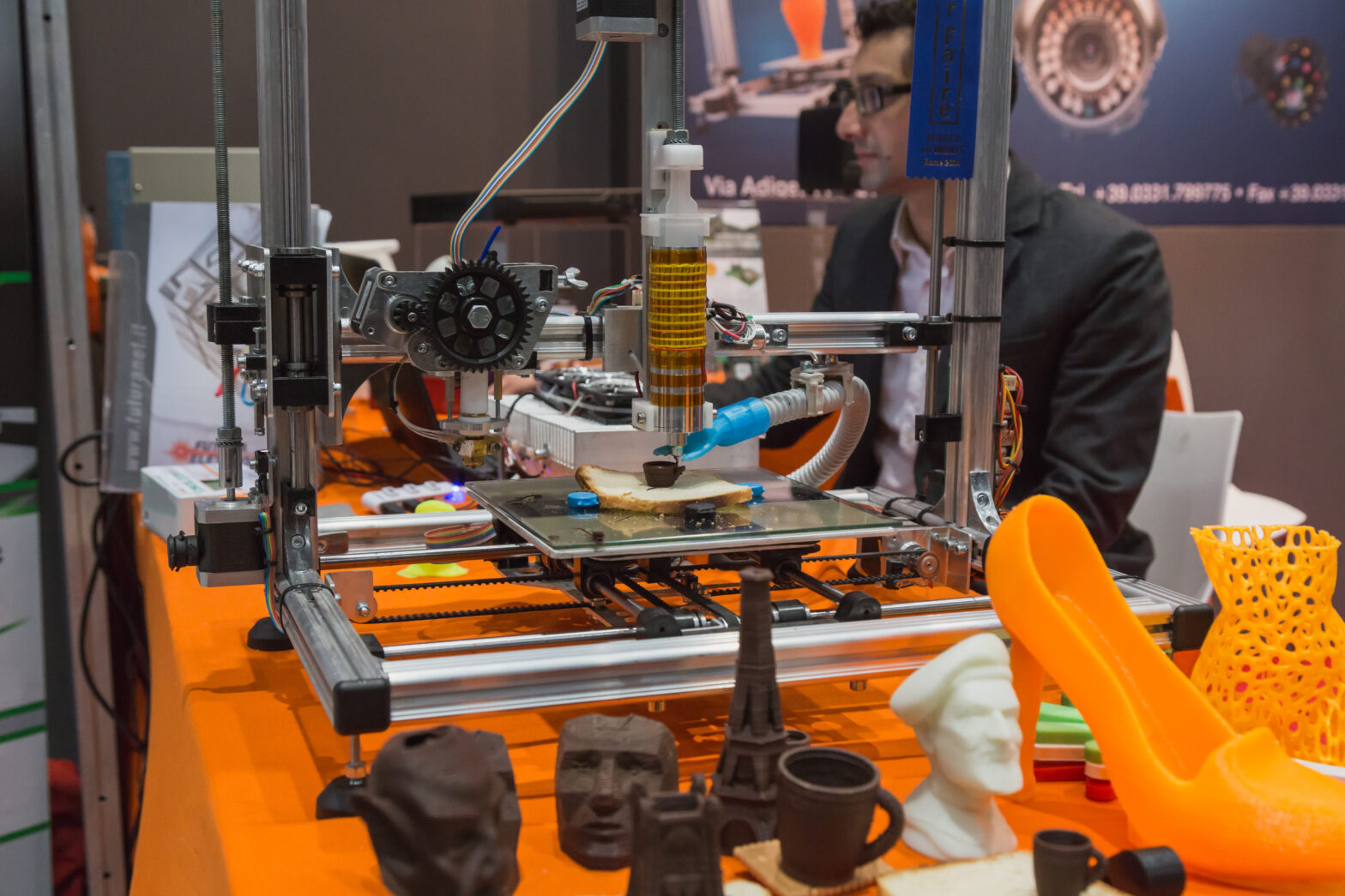

The impact of 3D printing on small businesses isn’t restricted to monetary gains, however. Due to the heightened design flexibility offered by 3D printers, businesses have the potential to produce an endless array of dynamic, visually appealing products that are beyond anything thus far released by modern manufacturers. How? Printer specialists, Toner Giant, explain the process used in 3D printing:

‘Put simply, 3D printers use an additive manufacturing method to create a three-dimensional object out of a digital file. The object is created when successive layers of a special additive are laid on top of each other. This process offers complete flexibility in terms of customisation, and will allow companies to create really exciting products – no matter what their industry.’

Whilst 3D printing is by no means an obligatory business tool yet, in the not-so-distant future the impact of 3D printers will undoubtedly be felt in all sectors, summoning a new era in the way small, medium and large companies go about their business.

See also: How 3D printing could improve the future of food

Will 3D printing change the world?

Here, we look at the 3D printing space and discuss the potential of the technology.

It seems everywhere you look these days there’s another story about 3D printers. Someone’s managed to print a dress. A new hand. A car. Even a five-storey building. Is this the future we were promised by The Jetsons and Star Trek? It certainly looks like it could turn out that way; but don’t expect a new industrial revolution just yet.

That’s not to say the technology is in its infancy. Printing in three dimensions was pioneered by Chuck Hall over 30 years ago, when he first patented his stereolithography system for producing fast, cost-effective prototype components. His technique worked by printing successive layers of light-reactive plastic on top of each other until the object was complete.

Since then, the technology has been adopted by major manufacturers including Boeing, General Motors and Mercedes Benz, but it is only just beginning to make an impact on the general public. Desktop 3D printers are one of the most popular categories on crowdfunding sites such as Kickstarter, indicating that there are lots of entrepreneurs who are looking to get into the market. They have also become readily available and comparatively affordable through high street retailers, but so far they have only really been embraced by designers, engineers and hobbyists.

One of the major drawbacks is the lack of a popular app or programme for designing 3D products that works across all printers. While websites like Thingiverse and Shapeways make it easy to download existing designs for printing, producing your own models is much more specialised. Current machines can generally only print in two types of plastic, although new materials that replicate wood, stone and even metal are coming on to the market.

There’s little doubt that one day we will be able to simply download and print out complex products, cutting out the manufacture, retail and supply chains, at which point 3D printing will revolutionise the way we shop. These products will become cheaper because we will no longer need factories, shops or mail delivery and their associated costs. They will also be easy to customise to your personal needs, as altering the product won’t require retooling at the factory, just a tweak of the instructions you download.

However, the technology has some way to go before this vision of the future becomes a reality. Whilst it’s true that over the last few years desktop machines available from specialists like Formlabs have become a lot more sophisticated, and prices have plummeted, it seems 3D printers won’t become as commonplace as their 2D counterparts any time soon. But no-one can deny the opportunities this technology offers for both consumers and manufacturers, and it’s potential to radically transform the way we shop.